About us

The company was established in

Registered capital

Current number of employees

Plant area

technical capability

Mold Development

Adhering to the concept of learning, absorption and innovation, Hengyongxin's technical team has constantly mastered the advanced technology in the industry, formed the core competitiveness with innovative independent intellectual property rights in the field of aluminum alloy die casting and plastic injection mold development, and shared technology and experience with customers.

Project development process

Die casting project - 3D/2D quotation - quotation confirmation - contract order - mold opening review - mold design - mold drawing confirmation - mold opening - mold testing - die casting - polishing and grinding - CNC fine processing - drilling and tapping - surface treatment - QC inspection - packaging and shipping

Main production equipment

8 sets of CNC, 4 sets of EDM, 18 injection molding machines (80T~400T), die-casting machines (300T, 400T, 600T, 800T, 1300T), 2 automatic sand blasting machines, 1 cleaning and passivation line, 1 baking line, 1 assembly line, as well as 3D and other testing equipment;

TRAILER

医疗器械

医疗器械

医疗器械

Products

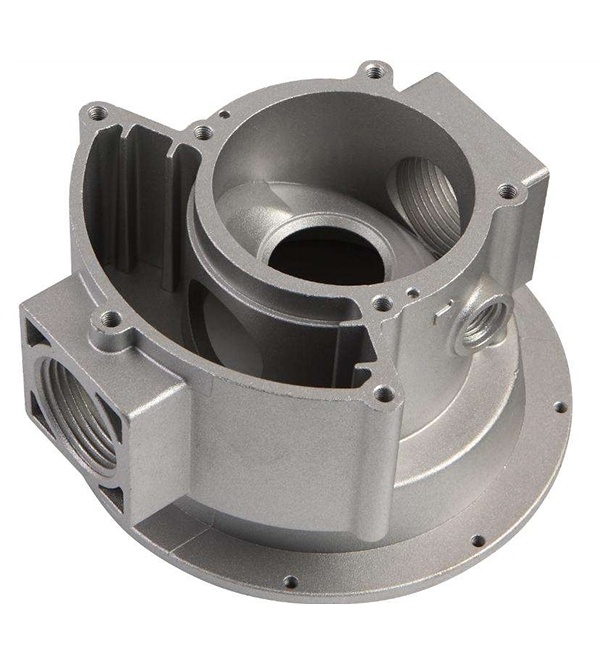

Die-cast products

New Energy Vehicle Controller Housing (4-in-1)

New Energy Vehicle Controller Housing

New Energy Vehicle Controller Housing (4-in-1)

New Energy Vehicle Controller Housing

News

Let's discuss measures to address the porosity issue in castings.

Pores, also known as air holes, are one of the common defects encountered in casting production. They typically appear inside, on the surface, or near the surface of castings, forming circular, elongated, or irregular shapes of varying sizes. Some pores occur individually, while others cluster together in patches. The pore walls are smooth and often exhibit a white color, sometimes even covered with a layer of oxide scale. Through long-term practice, we’ve categorized these defects—based on their distinct shapes and formation mechanisms—into types such as gas porosity, bubbles, pinholes, gas looseness, and gas shrinkage cavities.

12

2019.08

Precautions and Equipment Selection for Die Castings in New Energy Vehicles

Why does everyone use aluminum alloy materials for manufacturing? That’s because it doesn’t rust and can maintain reliable performance over the long term. Even so, proper storage is still essential—specifically, avoid letting the die-cast parts of new-energy vehicles come into contact with other chemical elements, as such contact could lead to unintended changes in the components.

Learn more

14

2019.08

The working principle of aluminum alloy die castings for new-energy vehicle die-cast parts

It requires a molding process that involves the integrated use of die casting machines and aluminum alloy components. The principle behind die casting technology is to inject molten metal at high speed into a precision metal mold cavity under high pressure, where the metal solidifies into a casting as it cools under pressure. Cold chamber and hot chamber die casting represent the two fundamental approaches in this technology. In cold chamber die casting, the molten metal is manually or automatically poured into the injection chamber, after which the plunger advances, forcing the molten metal into the mold cavity. In contrast, in hot chamber die casting, the injection chamber is positioned vertically above the mold cavity, allowing the molten metal to flow automatically through an inlet located on the chamber into the mold. A pressurized plunger then moves downward, pushing the molten metal through a gooseneck tube and into the mold cavity. Once the metal has solidified, the mold is opened.

Learn more

Copyright © Zhongshan Hengyongxin Precision Products Co., Ltd 粤ICP备16023498号 SEO Powered by www.300.cn