2019-08-10

Let's discuss measures to address the porosity issue in castings.

Pores, also known as air holes, are one of the common defects encountered in casting production. They typically appear inside, on the surface, or near the surface of castings, forming circular, elongated, or irregular shapes of varying sizes. Some pores occur individually, while others cluster together in patches. The pore walls are smooth and often exhibit a white color, sometimes even covered with a layer of oxide scale. Through long-term practice, we’ve categorized these defects—based on their distinct shapes and formation mechanisms—into types such as gas porosity, bubbles, pinholes, gas looseness, and gas shrinkage cavities.

2019-08-12

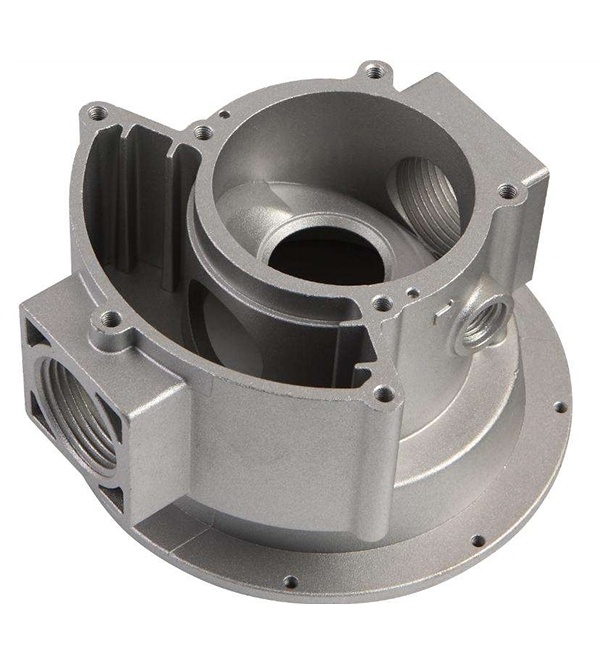

Precautions and Equipment Selection for Die Castings in New Energy Vehicles

Why does everyone use aluminum alloy materials for manufacturing? That’s because it doesn’t rust and can maintain reliable performance over the long term. Even so, proper storage is still essential—specifically, avoid letting the die-cast parts of new-energy vehicles come into contact with other chemical elements, as such contact could lead to unintended changes in the components.

2019-08-14

The working principle of aluminum alloy die castings for new-energy vehicle die-cast parts

It requires a molding process that involves the integrated use of die casting machines and aluminum alloy components. The principle behind die casting technology is to inject molten metal at high speed into a precision metal mold cavity under high pressure, where the metal solidifies into a casting as it cools under pressure. Cold chamber and hot chamber die casting represent the two fundamental approaches in this technology. In cold chamber die casting, the molten metal is manually or automatically poured into the injection chamber, after which the plunger advances, forcing the molten metal into the mold cavity. In contrast, in hot chamber die casting, the injection chamber is positioned vertically above the mold cavity, allowing the molten metal to flow automatically through an inlet located on the chamber into the mold. A pressurized plunger then moves downward, pushing the molten metal through a gooseneck tube and into the mold cavity. Once the metal has solidified, the mold is opened.

2019-08-16

The company is intensifying its research efforts and comprehensively advancing its brand strategy.

Our company was established in 2007 and is located in Torch Road, the Third Industrial Zone, Tanzhou Town, Zhongshan City. We specialize in the manufacturing and sale of various types of molds—including injection molds, die-casting molds, blow molds, rotational molds, rubber molds, and bakelite molds—as well as offering high-quality injection molding services, custom processing based on provided drawings or samples, and precision metal product fabrication, along with the production of specialized tooling and fixtures. Currently, our key clients include publicly listed Guangdong Dehao Runda Electrical Co., Ltd., a leading domestic high-tech enterprise; Zhuhai Yingboer Electric Co., Ltd., a renowned innovator in the industry; and Zhuhai Baoying Automation Equipment Co., Ltd., among others. Our company has successfully achieved ISO9001 certification for its quality management system.

2019-08-20

Zhongshan Hengyongxin Precision Products Co., Ltd. Launches New Website

Our company was established in 2007 and is located in Torch Road, the Third Industrial Zone, Tanzhou Town, Zhongshan City. We specialize in the manufacturing and sale of various types of molds—including injection molds, die-casting molds, blow molds, rotational molds, rubber molds, and bakelite molds—as well as offering high-quality injection molding services, custom processing based on provided drawings or samples, and precision metal product fabrication, along with the production of specialized tooling and fixtures. Currently, our key clients include Guangdong Dehao Runda Electrical Co., Ltd., a publicly listed company; Zhuhai Yingboer Electrical Co., Ltd., a renowned domestic high-tech enterprise; and Zhuhai Baoying Automation Equipment Co., Ltd., among others. Our company has successfully achieved ISO9001 certification for its quality management system.

2021-07-08

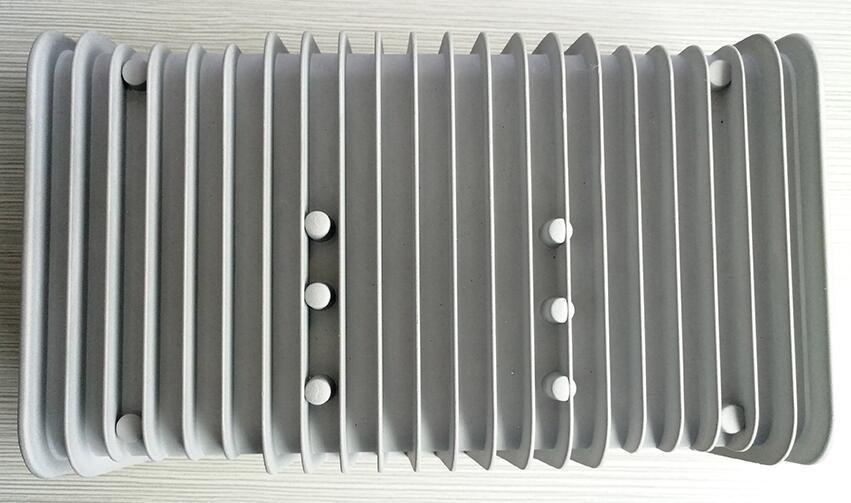

Key Considerations for Aluminum Alloy Die Casting Design

The rationality of die casting design is related to the whole process of die casting. When designing die castings, the structural characteristics and process requirements of die casting should be fully considered, so as to minimize the occurrence of defects in the process of die casting, and to maximize the quality of die castings with the best design scheme.

Copyright © Zhongshan Hengyongxin Precision Products Co., Ltd 粤ICP备16023498号 SEO Powered by www.300.cn