2019-08-10

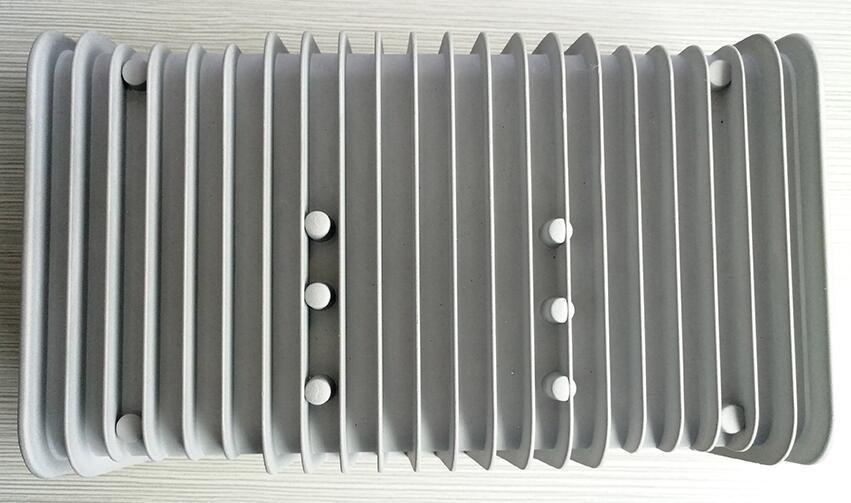

Let's discuss measures to address the porosity issue in castings.

Pores, also known as air holes, are one of the common defects encountered in casting production. They typically appear inside, on the surface, or near the surface of castings, forming circular, elongated, or irregular shapes of varying sizes. Some pores occur individually, while others cluster together in patches. The pore walls are smooth and often exhibit a white color, sometimes even covered with a layer of oxide scale. Through long-term practice, we’ve categorized these defects—based on their distinct shapes and formation mechanisms—into types such as gas porosity, bubbles, pinholes, gas looseness, and gas shrinkage cavities.

2019-08-12

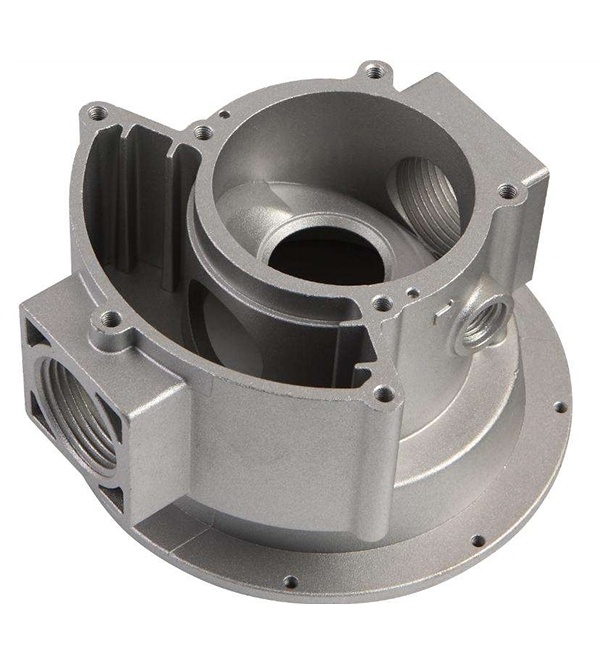

Precautions and Equipment Selection for Die Castings in New Energy Vehicles

Why does everyone use aluminum alloy materials for manufacturing? That’s because it doesn’t rust and can maintain reliable performance over the long term. Even so, proper storage is still essential—specifically, avoid letting the die-cast parts of new-energy vehicles come into contact with other chemical elements, as such contact could lead to unintended changes in the components.

Copyright © Zhongshan Hengyongxin Precision Products Co., Ltd 粤ICP备16023498号 SEO Powered by www.300.cn